Overarching Design Mission:

To change the dialogue and perception of robotics, A.I and automation.

Every technological advance has created a web of complementary industries, a demand for new skill sets and employment opportunities. Eg. automotive, food production, consumer electronics etc.

There is a cognizant effort towards designing a product that expands the industry’s roles and the technical skills of its workers.

Automating floor cleaning frees up time for the workers to tend to higher value tasks, complete their daily roles with less competing duties and elevating their job role with new technical skills. Because the cleaning professionals will be utilizing the robot daily, they are the ideal candidates to be technicians and official operators of the robot and leaders in training others.

Exposing new demographics to cutting edge technologies also prepares them for future technological advances, thus creating a more knowledgeable workforce of people with less trepidation to change. This benefits both employees and employers.

High Level Goal

Apply scientist research and development data, navigation AI and sensor based mapping capabilities, to automate a manual machine capable of maneuvering through dynamically changing indoor environments.

Initial vertical: B2B: Sanitation/Janitorial Industry

PRODUCT 1 | AUTONOMOUS FLOOR SCRUBBER

Users (USA/JAPAN/CHINA)

Cleaning professional - direct control/daily use

Managers - Assigning a person to the robot, planning store cleaning areas

Business parties - Purchaser, reviewer of reporting data, key decisions maker

Environment bystanders - People present during robot operation (customers, workers not involved with the robot)

Technicians - People maintaining, calibrating and repairing the machine

Customer support - External facing

Development teams - Engineering, manufacturing, deploying, training

Research/Testing Methods

Target customer site observation

Prototype (machine components, UI elements)

Hallway testing (internal/external)

Interview

Field use/observation of existing machines

Environment testing (hardware/sensors)

Workflow testing (mapping, teaching the machine, running autonomous routes)

End of line usability testing

3D CAMERA / SENSOR VIEW FOR AI NAVIGATION

Industry considerations:

- Janitorial industry - employment high turnover (USA)

- Janitorial industry is a transition to retirement (Japan)

- In Japan and various areas of USA, employers have trouble filling positions.

- New market for technology to improve ROI for employers and elevate roles for cleaning professionals.

- Many janitorial professionals are hired through contracting services and must confine their extensive tasks to an allotted duration. Certain tasks do not get fulfilled in their entirety, which affects the client and the cleaning service.

Social Design Considerations:

Janitorial:

A recurring social concern surrounding the advancement of automation and robotics is the reduction or elimination of existing employment roles for humans. The industry is multicultural, where the majority of workers come from varying ethnicities, speak different languages and English is not always fluently spoken.

Janitorial Employers:

Employers face industry high turnover, a shortage of available workers and difficulty meeting customer facility requirements, based on available resources and time.

Product Design Problems:

1. Create a robot that is a tool for humans, rather than one eliminating an employment role.

Legacy design language:

Design a robot that does not look like a robot. Rather than a futuristic approach to the industrial design, utilize shapes, textures, hardware and familiar elements from past/current industrial machines.

Creating a machine with analogous elements to those that the workers use daily, will aid in a bulk of the on-boarding, leaving the remaining learning curve to be limited to the autonomy portion.

Maintain the seat, elevated on the top of the machine exhibiting that there is a permanent place for a person and that person is placed in a position of control over the machine.

By automating a manual machine, businesses do not lose functionality, but are gaining enhanced features. The machine can always be utilized manually, but has autonomous capability.

2. Define how a human will interface with the robot (workers and environment humans).

Inputs/outputs:

Digital display UI and membrane panel buttons, separating manual functions and autonomous features. This makes machine operational controls readily available and customizable for manual and autonomous use.

Hardware inputs, go/pause rear button. When the user initiates autonomy, the machine is moving away from the person.

Audible sounds to notify surrounding areas of the machine’s presence and status.

Visual LED blinkers to display directional intent.

Top large dome led to indicate that the machine is operational.

Whiteboard session on hardware mechanics and methods in enabling the user to teach the robot to map a space.

3. Integration of the robot, with a janitor’s existing workflow, while proving an ROI for the customer.

4. On boarding non-technical individuals, to use the robot and map environments.

Mapping:

Robot raw map data/path planning

Create a mapping workflow parallel to that of the janitor’s workflow, when they are cleaning the floors.

Janitor will initiate a “teach mode” on the robot, then the janitor can clean the floor as they usually would and the robot will begin learning the path and mapping the space, to clean autonomously, in the future

Generation 1 UX Hardware Constraints:

Strict BOM product cost.

Multiple mediums of inputs and outputs

Hybrid software and hardware interactions.

No vocal commands or communications.

Whiteboard hardware/firmware workflow for soft vs hard estop behaviors.

Delivered G1 Product

RS26 Floor Scrubber - Autonomous/Manual function

Sensors: Time of Flight camera, LIDAR (lighting detection and range), Sonar, IFM laser sensor.

Hardware inputs: Membrane panel with cleaning controls, digital display, emergency stop, blue illuminated go/pause button.

Autonomy UI Workflow

Generation 1 Post mortem

Early in the project, there was a dominant focus on the display interface and how that UI architecture would be structured for the teaching/mapping/ and navigation AI portion.

In hindsight, something applied to later generations and form factors of our products, is the involvement with the firmware/hardware engineering discussions, during the conception phases.

Conversations surrounding items like sensor placement, hardware selection, low level development pieces and more, helped me to understand the guts of the product, it’s strengths and limitations and aided in designing a holistic machine, despite the segmented dichotomy between being autonomous and manual.

---

Case study for generation 1 (2016-2017)

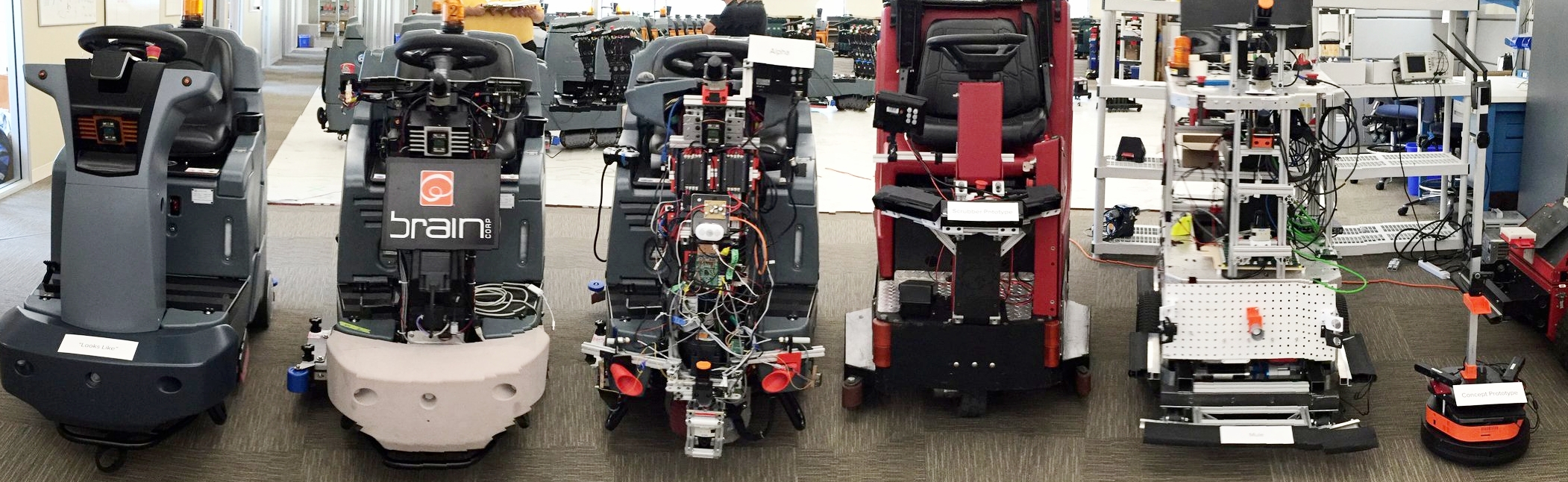

Design research, architecture and language applied to the following:

Generation 2 of the floor cleaning machine (2017) and international NDA products 1 & 2 (2018)